Stratasys

Company

History

I wrote and curated this timeline as part of the launch campaign for the world’s first full-color, multi-material 3D printer. The campaign tagline—“Stratasys Invents 3D Printing. Again.”—called for a story that celebrated the company’s legacy of innovation.

Originally published as an interactive experience, the timeline traced Stratasys’ evolution from kitchen-table startup to global tech pioneer. I highlighted key milestones, breakthroughs, and human moments to make the technical history both engaging and accessible.

The version below includes the full copy and imagery, showing how strong structure and storytelling can bring a company’s history to life.

Stratasys History

1988

Scott Crump Invents FDM Technology

In 1988, a young engineer frustrated by a sluggish prototyping process chose to reimagine it rather than accept it. His invention, FDM Technology, marked the inception of Stratasys as a company and a major milestone in the history of 3D printing.

1989

A Hobby Becomes A Business

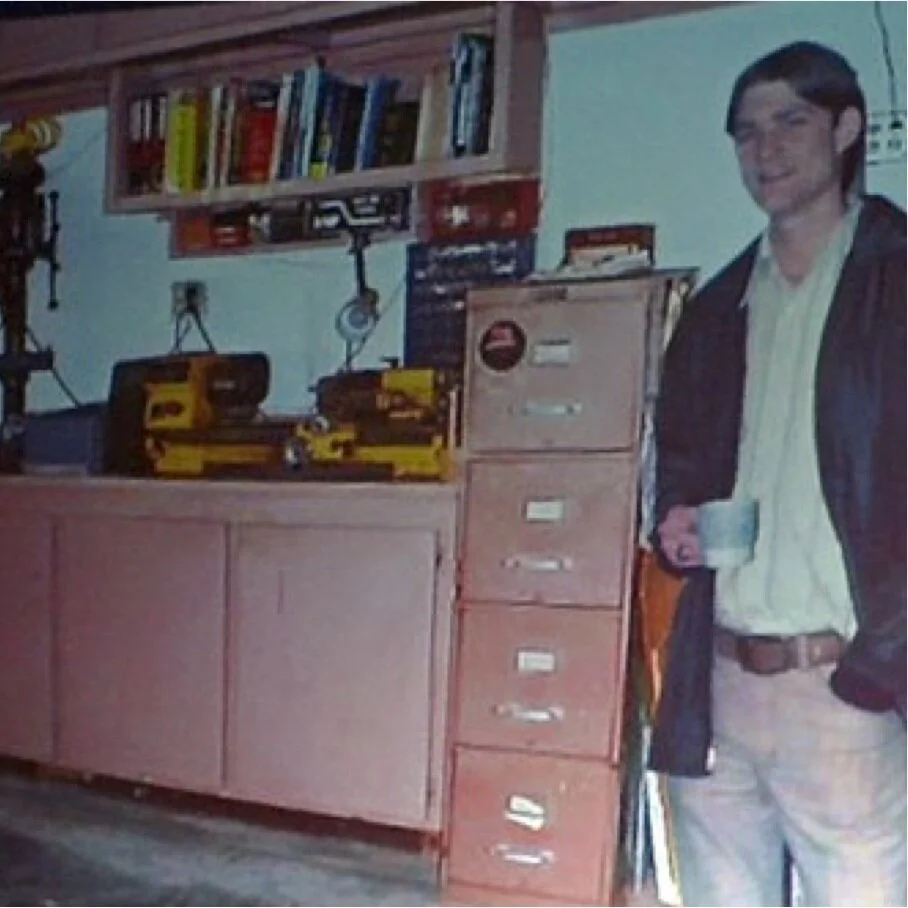

Scott Crump’s first FDM prototype was both simple and clever: he extruded a mix of candle wax and polyethylene from a hot-glue gun to 3D print a toy frog for his daughter.

He spent weekends refining the idea, eventually automating it with a modified 2D plotter. When the hobby outgrew the family kitchen, Crump and his wife Lisa founded Stratasys and shipped their first unit in 1991.

1992

Stratasys Ships First Units

Despite selling a total of only five units in the company's first three years—parts of which were built using chrome auto parts and vacuum cleaner tubes—the Crumps' confidence in the promise of FDM Technology didn't waiver. With several exciting innovations in the pipeline, Stratasys was still just getting started.

1993

FDM Works With Popular ABS Thermoplastic

In a burst of innovation, Stratasys introduced the first ABS material to work with FDM, as well as a dual delivery system that extruded a removable support material. This combination made stronger, more complex FDM parts possible.

1994

Stratasys Goes Public

Stratasys funded its future corporate growth through an initial public offering in 1994. Its stock began trading on the NASDAQ Exchange (SSYS) at $5 per share.

1995

Stratasys Files Trademark for "3D Printer" Term

Stratasys filed a trademark for the term "3D Printer" after co-developing a small desktop system with IBM. Stratasys would drop its claim to the term in 1999.

1996

Growth is Strong

In 1996, not long after its IPO, Stratasys achieved unprecedented growth, shipping 60% more units than its nearest competitor.

1998

Inkjet Entrepreneurs Found Objet Geometries

Inventors and printing-industry entrepreneurs Rami Bonen, Gershon Miller and Hanan Gotaiit began development on a new 3D printing process based on familiar inkjet technology.

1999

FDM Tested in Microgravity

A Stratasys FDM 1600 was flown aboard the NASA KC-135 Reduced Gravity Aircraft to assess the feasibility of using FDM in a microgravity environment.

Observing how layers bonded, how unsupported structures behaved, and how dimensional stability compared with the same designs built on the ground, experimenters determined that FDM technology could feasibly produce parts in reduced gravity.

2000

Objet Unveils First "Inkjet" 3D Printer

The Objet Quadra was introduced at the National Design Engineering Show at McCormick Place, Chicago on March 13. It was the first and only 3D printer to jet a liquid, photo-curable polymer.

The following year, Objet introduced Tempo, with improved photo-curing and support structures.

2002

3D Printed Model Aids Separation of Conjoined Twins

Maria Teresa and Maria de Jesus Quiej-Alvarez were born with separate, complete brains, but with intertwining blood vessels that made separation a challenge. With help from a 3D printed planning model, the operation to separate the twins took about 22 hours. For comparison, Biomedical founder Eitan Priluck said that similar procedures had taken as long as 97 hours in the past.

2007

Objet Introduces Multi-Material 3D Printing

Objet unveiled its PolyJet Matrix Technology and introduced the world’s first 3D printer to simultaneously jet multiple materials. The Connex500 won the EuroMold 2007 Innovation Award.

2009

Stratasys Unveils First High-Performance FDM Plastic

To meet the needs of high-requirement aerospace, automotive and military applications, SABIC's ULTEM 9085 resin was chosen to run on FDM systems based on its FST rating, high strength-to-weight ratio and existing certifications.

2010

3D Printed Exoskeleton Lets Little Girl Lift Arms and Play

Using a Dimension 3D printer, researchers at the Alfred I. duPont Hospital for Children in Philadelphia were able to create what little Emma called her "magic arms." The device is a custom-designed exoskeleton that enables her to conquer limited joint mobility and underdeveloped muscles.

2012

NASA’s Human-Supporting Rover Uses FDM Parts

About 70 of the parts that make up the rover were built directly from computer designs in the heated chamber of a production-grade Stratasys 3D Printer.

2012

Objet and Stratasys Merge

David Reis, chief executive officer of the new combined company, stated, "We are excited to move forward as one company and deliver the benefits this combination creates for our shareholders, our customers and our employees."

2013

Stratasys Acquires MakerBot

“MakerBot's 3D printers are rapidly being adopted by CAD-trained designers and engineers," said Stratasys CEO David Reis at the time of the merger. "Bre Pettis and his team at MakerBot have built the strongest brand in the desktop 3D printer category."

2014

Stratasys Introduces First Color and Multi-material 3D Printer

Objet500 Connex3 was the first 3D printer in the world to simultaneously 3D print multiple colors and materials. Today Connex3 sets the industry standard for multi-material 3D printing.

2014

Stratasys Acquires GrabCad

The addition of GrabCAD Workbench would strengthen Stratasys' role in facilitating collaboration among its growing user community, while streamlining the design-to-3D print process.

2015

Stratasys Bolsters Manufacturing Services

Stratasys combined three leading 3D printing service bureaus to form Stratasys Direct Manufacturing. As the new face of advanced manufacturing services, Stratasys Direct Manufacturing helps companies in diverse industries create extraordinary new products at every phase of the production process.

2016

Stratasys Invents 3D Printing. Again.

The Stratasys J750 3D Printer isn’t just the latest addition to the PolyJet portfolio. It’s the first-ever full-color, multi-material 3D printer. For anyone who has endured the frustration of inconsistent color results, multi-step curing, extensive finishing steps, or restrictive color and material options, this system will change the way they look at 3D printing.